The best 4 FEATURES YOUR LASER CUTTING Support VENDO

Wiki Article

Laser cutting is really a producing procedure used to provide customized shapes and patterns with the usage of a substantial-driven laser beam. Laser cutting is commonly used in the automotive, musical instrument and healthcare device industries mainly because it is appropriate for a wide range of products, including metallic, plastic, Wooden, glass, paper and gemstones, to create intricate, exact and sophisticated sections.

To produce these pieces, laser reducing services suppliers use amongst three differing kinds of laser cutting: fusion reducing, oxidation reducing or scribing. Each approach normally provides less contamination, Bodily injury and waste, which contributes to content cost personal savings for that maker.

This website post is intended to help you obtain an improved understanding of the laser reducing course of action so that you will be perfectly educated in choosing the ideal laser slicing support seller.

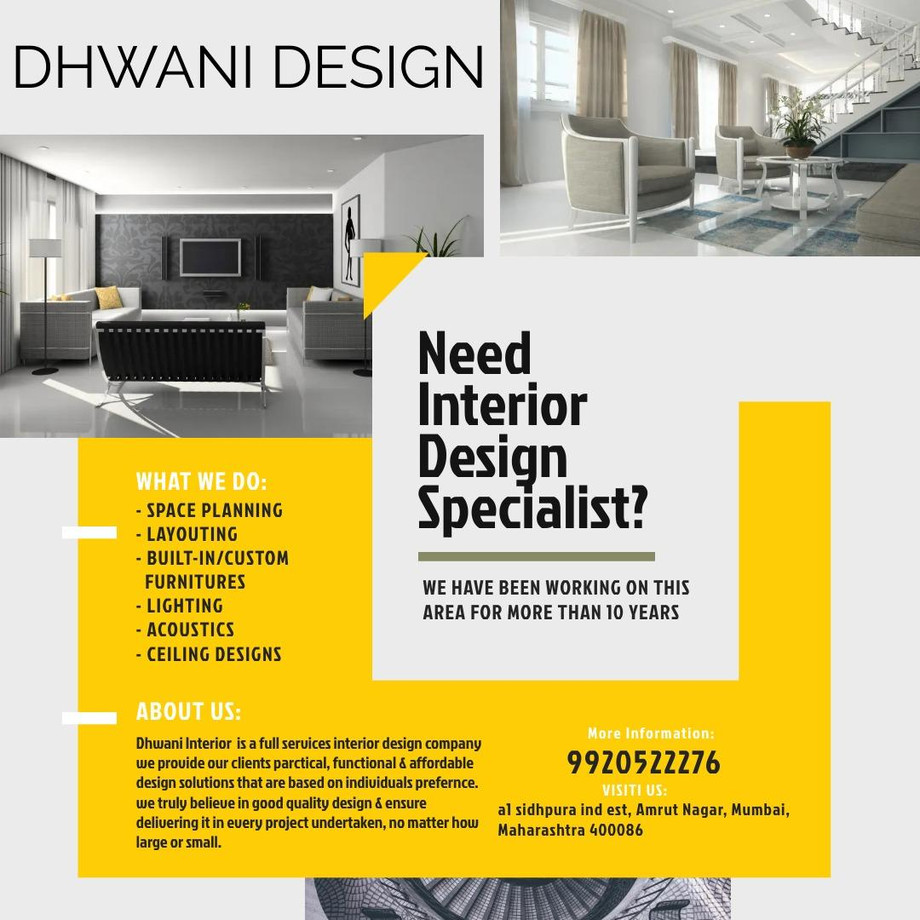

best Laser Cutting Service Provider in Mumbai Dhwani Design

The Laser Reducing Approach and Equipment

Laser chopping is a thermal-primarily based, non-Get in touch with fabrication method suitable for slicing steel and non-metallic resources. Not like mechanical reducing, which makes use of electricity-driven reducing machines, laser slicing takes advantage of a laser cutting equipment to provide cuts, markings and engravings.

The Laser Slicing Process

Fundamental laser cutting is made of the the subsequent phases:

Beam era: The laser beam is generated as a result of spontaneous or stimulated emission.

Beam concentrating: The beam enters in the nozzle that directs the area of effect.

Localized heating and melting: The beam is absorbed by the material that will increase in inner Vitality and heat era.

Material ejection: As part of the heating and melting procedure, regions of the material are vaporized to produce the desired Lower.

Beam motion: Movement and slicing are attained via reflective mirrors, laser head motion or workpiece manipulation.

Each and every phase is essential on the laser chopping process and creating a specific Slice. Dependant upon the content and kind of Minimize, laser reducing also employs inert or active support gasses.

Different types of Laser Cutting Machines

Whilst laser chopping machines differ in subtle means from a person model to the next, a laser reducing machine is typically build to incorporate a laser resonator assembly, mirrors plus a laser slicing head, which contains a laser concentrating lens, a nozzle along with a pressurized fuel assembly.

The differing types of laser cutting machines are classified into fuel, liquid and stable-condition lasers. The key two sorts of lasers employed by laser equipment are CO2 and sound-point out lasers:

CO2 lasers: These are utilized to Slice non-metallic resources. Even though laser technological innovation has evolved to enable CO2 lasers to cut metal, they are still improved fitted to chopping via elements for instance rubber, leather-based or wood.

Strong-point out lasers: These are generally made from crystal or fiber that make it possible for for top-powered metallic slicing. Crystal lasers are very flexible in terms of fabric slicing abilities. Having said that, they are generally costlier and possess shorter lifespans. Alternatively, fiber lasers are cheaper and for a longer period lasting.

When studying a laser reducing services seller, make sure to find out which kind of laser devices they've of their equipment set. As you'll be able to see, there are a number of various devices that happen to be more suited to particular jobs, and not all producers have each piece of equipment obtainable.

Some great benefits of Laser Chopping

Laser slicing provides a number of rewards—including flexibility, repeatability, Expense-performance and speed—inside the manufacturing means of exact, high-high quality and multipurpose elements. By using most effective techniques, your laser reducing assistance seller should provide the next functions:

a. Slicing Precision and Precision

As opposed to most common slicing equipment, laser chopping devices generate a variety of cuts and styles which provide more precision and precision. Laser cutting devices are usually totally CNC managed, which suggests that they've superior repeatability in generating finish, intricate sections. The significant-good quality cuts made by lasers generally do not need to have further cleaning, managing or ending, which decreases the need for secondary procedures.

b. Much less Substance Contamination and Squander

Since lasers use a focused beam which allows for narrower kerf widths, the level of product eradicated is minimized. With nominal thermal input from localized heating, the warmth-impacted zones are minimized, which also decreases the thermal distortion. If thermal temperatures are also large, the fabric could be damaged, rendering the element ineffective.

c. Reduce Routine maintenance and Fix Prices

When compared with other chopping equipment, maintenance fees for laser slicing products are reasonably small. In addition, laser reducing equipment don't demand transforming out individual equipment to carry out diverse functions, which decreases equally the gear prices and lead time amongst procedures. At last, laser components practical experience a lot less exhaustion mainly because laser cutting is a non-Call method.

d. Larger Operator Protection

Laser reducing has a decreased danger of operator personal injury as it employs minor to no mechanical parts. That has a tranquil operation, laser slicing is much less distracting than louder processes. With a lot less interaction While using the device and less sounds, the overall office surroundings is safer.

Choose the Effectively-Geared up Laser Chopping Services Vendor

By deciding on Dhwani Design as your laser reducing service seller, you will have a crew Together with the abilities and machinery to work with various elements, meet sophisticated demands and provide the proper prototype persistently, promptly and within budget. Report this wiki page